impactcrusherimpactcrusherimpactcrusher

.jpg)

Impact crushers highquality impactors

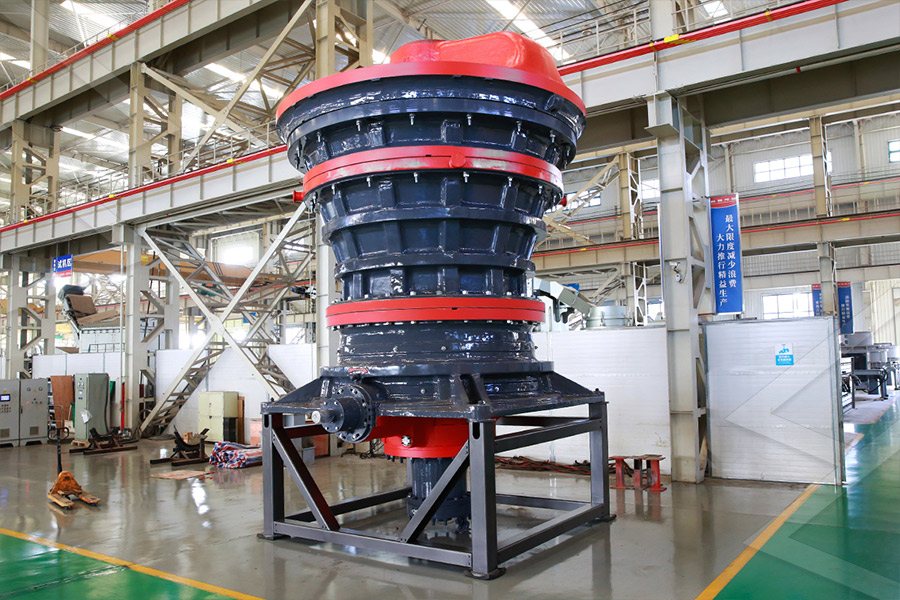

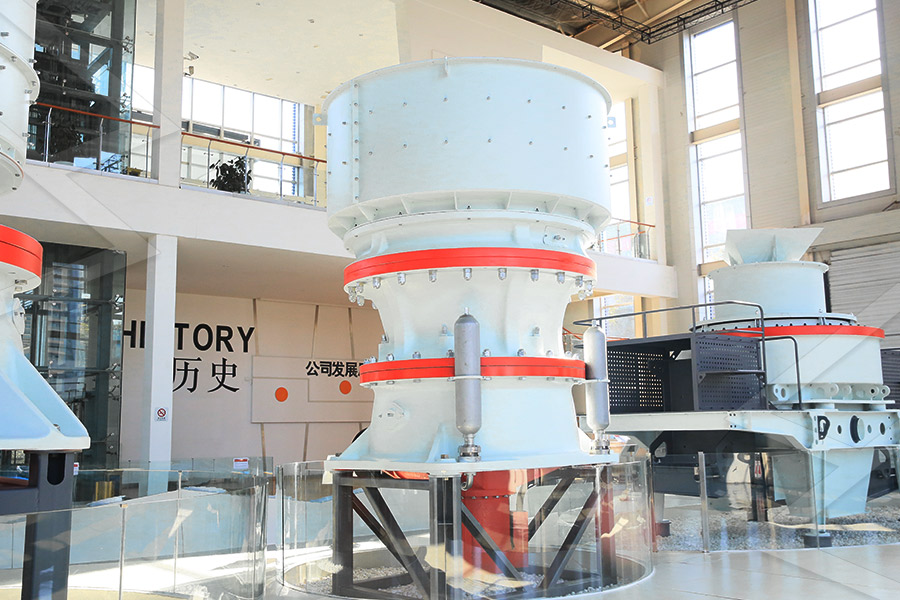

Features Impact crushers are utilized in aggregates production, mining operations, as well as in recycling applications Depending on the type of an impact crusher, they are known 2024年6月28日 Impact Crusher Impact crusher is generally used for aggregate production, mining operations, and concrete recycling and crushing; it is known for its high crushing Impact crushers highquality impactors from Baichy

.jpg)

Impact Crusher an overview ScienceDirect Topics

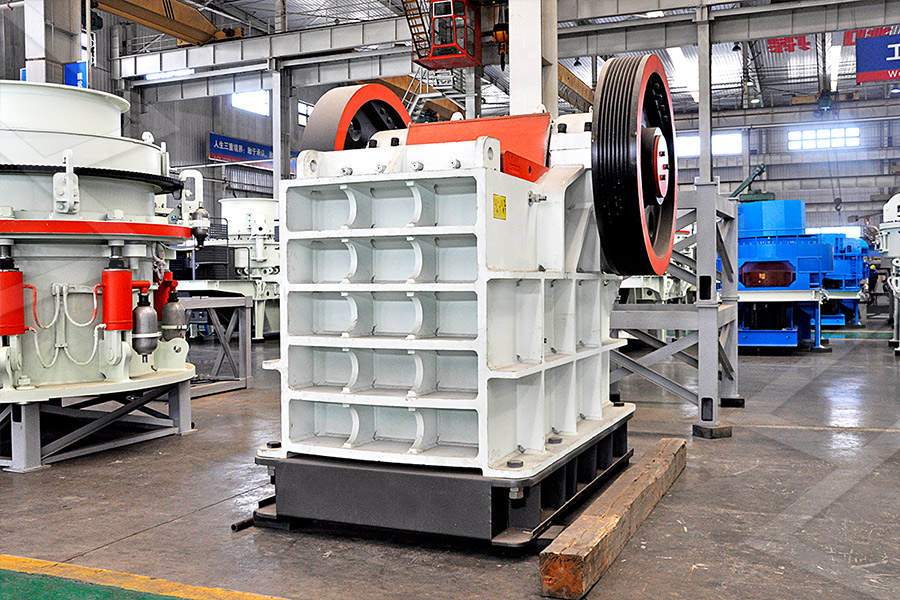

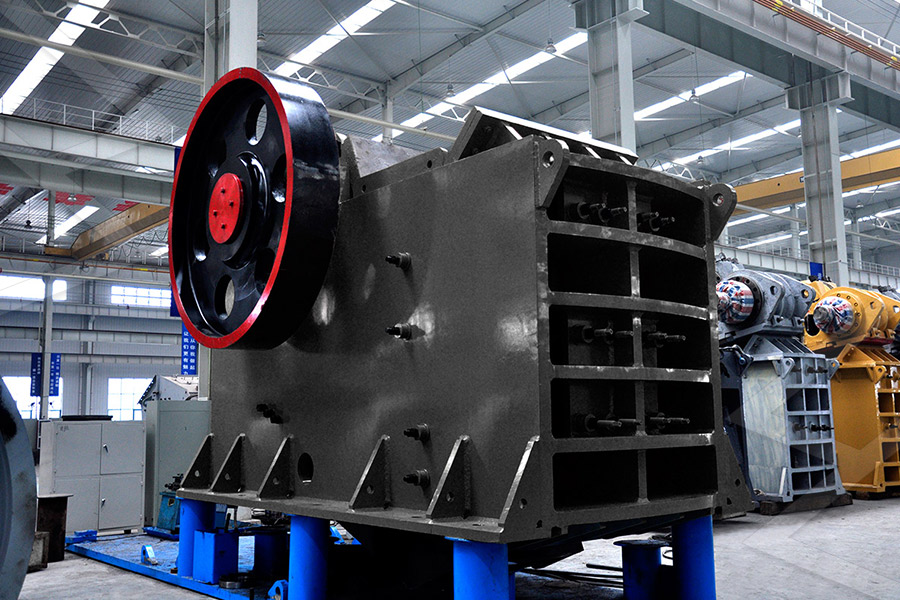

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force 2023年3月11日 An impact crusher is a machine used to crush materials by impact energy It works by feeding the material into a rotating rotor, which is equipped with a series of hammers As the rotor spins, the How Impact Crushers Work: A Comprehensive

Impact Crusher Fodamon Machinery

Impact Crusher Impact crusher is mainly used to crush many kinds of large, medium, small hard size materials with compression resistance no more than 350Mpa,in the fields of highway, reservoir, railway, airport 3 天之前 HC/EHSI Series Impact Crusher By many years experience, Sanme has developed the HC Series lmpact Crusher with advanced level The crushing chamber is Impact Crusher, impact crusher manufacturer SHANGHAI

I4C Impact Crusher McCloskey International

6 天之前 IMPACT CRUSHER RANGE CATALOG The McCloskey® I4C heavy duty compact impact crusher combines mobility, power and new features to deliver the highest production across applications and Imperial / metric Impact crushers (impactors) reduce mineral materials such as concrete, asphalt, and rock in size producing a cuboid product Learn how impact crushers workHow does an impact crusher work? RUBBLE

Mobile Impact Crushers Compact Impact

RUBBLE MASTER mobile impact crushers use a proven and powerful dieselelectric drivetrain Contrary to many traditional crusher manufacturers RUBBLE MASTER has been using this highly efficient 2024年6月10日 Product Insights Horizontal shaft impact crushers (impact crushers for short) utilize horizontal rotors to strike stones at high speeds, reducing their sizes The materials produced by impact crushers take on cubic shapes, which are believed to enhance the strength of concrete, making them ideal machines in the aggregate and recycling Impact Crusher, Horizontal Shaft Impactor GEP ECOTECH

.jpg)

Track Mounted Impact Crusher Cobra 290R

2024年7月4日 Impact Crusher The Cobra 290R is a versatile and easy to use Track Mounted Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Our impact crushers Impactors: The heart of stationary, semimobile and mobile crushing plantsIMPACT CRUSHERS

.jpg)

Types of Crushers: What You Need to Know

2023年8月2日 Brief history of crushers The first United States patent for a rock crushing machine was in 1830 Its key technology was the drop hammer concept, found in the wellknown stamp mill, which would be repeatedly linked to the golden age of mining Ten years later, another US patent was issued to an impact crusher The primitive impact crusher 2024年6月29日 The ® Trakpactor 260SR is a compact impact crusher which has been designed to offer excellent reduction and high consistency of product yield With its compact design and ease of mobility, the Trakpactor 260SR is primarily suited to recycling, demolition, and mining applications A postscreen system and recirculating conveyor Impact Crusher Trakpactor 260SR

What is an impact crusher and how does it work LinkedIn

2023年2月27日 An impact crusher is a machine used to break down materials into smaller pieces by striking them with a highspeed rotating rotor that contains a series of hammers or blow bars The materials are 2018年12月18日 NP impact crusher components The main components of the NP Impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates In small mobile machines (NP1110 and NP1213), there is only one breaker plate NP series impact crushers Wear parts

.jpg)

Mathematical modeling of a vertical shaft impact crusher using

2017年9月1日 Several mathematical models for the VSI crusher have been proposed in the last two decades or so The Whiten crusher model, originally developed for cone crushers, has served as the basis of several approaches to model VSI crushers In the present work, the Andersen/Awachie/Whiten model has been used as the basis for 2023年6月29日 An impact crusher is a type of crushing machine that uses striking force to break up materials Its working principle is based on using an external force to apply pressure and cause the material What is an impact crusher and what is its working principle?

Application guide ® NP Series™ impact

2022年1月31日 Maintenance tools 14 3 Application guide ® NP SeriesTM impact crusher wear parts Maximize the potential of your impact crusher2021年12月3日 Some scenes of the crushing screening plant considered in this study a) Location map of the plant b) Cone crusher c) Vertical shaft impact crusher d) Screens e) Railway ballast aggregates(PDF) INVESTIGATION OF ROCK AGGREGATE

Impact Crusher vs Jaw Crusher: Which One is

Considering which crusher to use for your project, it’s important to understand the difference between an impact crusher and a jaw crusher The two machines have different applicationsWhat is an Impact Crusher? Impact crushers rely on gravitational or dynamic physical impact for size reduction of materials such as rock, concrete, gravel, and more, rather than through a standard compressiononly method of crushing Typically, impact crushers either use gravity to drop material onto a surface, or the material is fed into a chamber containing a Impact Crusher Machines Williams Patent Crusher

]@S0{UDKK%G24F3JGHC.jpg)

Impact crusher PF1315 Aggregate Rock Crushing

2023年11月10日 Impact crusher PF1315 is a crushing equipment that uses impact energy to crush materials It is a mediumsized stone crushing equipment with three crushing chambers and a large crushing ratioImpact crusher spare parts ’s impact crusher spare parts are known for ease of maintenance and reliability They enable better process control and a stable production pace when processing rock, sand, gravel or recycled Impact crusher parts

.jpg)

(PDF) Numerical Simulation of a Single and DoubleRotor Impact Crusher

2022年1月25日 However, the energy associated with the double impeller impact crusher is much higher and energy intensification, rather than energy efficiency, is the main gain of the double impeller designThe Willpactor® impact crusher design includes all the rugged construction features you expect in a Williams machine, plus it allows you to control product size while in operation without opening the crusher or changing parts The Williams Willpactor® primary impact crusher can be utilized for a variety of applications such as concrete or cement crushing, Willpactor® Primary Impact Crusher Williams Crusher

Minerals Free FullText Milling Studies in an Impact Crusher

2021年3月20日 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and product size distribution The experiments involved feeding a fixed mass of particles through a funnel into the crusher up to four times, and monitoring the grinding achieved with each Cone VS Impact Crusher The APF series crusher is an impact crusher for sale Philippines developed by AIMIX Group in the absorption of advanced technology and combined with the domestic sand and gravel industry With special structural design and advanced manufacturing technology, the impact rock crusher is widely used in coarse, medium, and Impact Crusher For Sale Philippines 37~400tph Capacity

.jpg)

Mobile Impact Crushers Compact Impact

RUBBLE MASTER's line of Mobile Impact Crushers recycle concrete and asphalt and crush natural rock with ease Production capacity range from 90 to 385 TPH2024年6月10日 Product Insights Horizontal shaft impact crushers (impact crushers for short) utilize horizontal rotors to strike stones at high speeds, reducing their sizes The materials produced by impact crushers take on cubic shapes, which are believed to enhance the strength of concrete, making them ideal machines in the aggregate and recycling Impact Crusher, Horizontal Shaft Impactor GEP ECOTECH

Track Mounted Impact Crusher Cobra 290R

2024年7月4日 Impact Crusher The Cobra 290R is a versatile and easy to use Track Mounted Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Our impact crushers Impactors: The heart of stationary, semimobile and mobile crushing plantsIMPACT CRUSHERS

Types of Crushers: What You Need to Know

2023年8月2日 Brief history of crushers The first United States patent for a rock crushing machine was in 1830 Its key technology was the drop hammer concept, found in the wellknown stamp mill, which would be repeatedly linked to the golden age of mining Ten years later, another US patent was issued to an impact crusher The primitive impact crusher 2024年6月29日 The ® Trakpactor 260SR is a compact impact crusher which has been designed to offer excellent reduction and high consistency of product yield With its compact design and ease of mobility, the Trakpactor 260SR is primarily suited to recycling, demolition, and mining applications A postscreen system and recirculating conveyor Impact Crusher Trakpactor 260SR

.jpg)

What is an impact crusher and how does it work LinkedIn

2023年2月27日 An impact crusher is a machine used to break down materials into smaller pieces by striking them with a highspeed rotating rotor that contains a series of hammers or blow bars The materials are 2018年12月18日 NP impact crusher components The main components of the NP Impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates In small mobile machines (NP1110 and NP1213), there is only one breaker plate NP series impact crushers Wear parts

.jpg)

Mathematical modeling of a vertical shaft impact crusher using

2017年9月1日 Several mathematical models for the VSI crusher have been proposed in the last two decades or so The Whiten crusher model, originally developed for cone crushers, has served as the basis of several approaches to model VSI crushers In the present work, the Andersen/Awachie/Whiten model has been used as the basis for 2023年6月29日 An impact crusher is a type of crushing machine that uses striking force to break up materials Its working principle is based on using an external force to apply pressure and cause the material What is an impact crusher and what is its working principle?